05-23-03 03:10

No 434934

When brominating eg. propiophenone with elementar bromine in DCM the reaction proceeds smoothly and rapidly with close to quantitative yields. When bromine is generated in situ using either a two-phase system of oxone/NaBr/DCM/water or H2O2/H2SO4/NaBr/DCM/water (with propiophenone present in the DCM phase) the reaction refuses to take place despite a reaction time of 20 hours at room temp.

Does someone have a explanation or theory why?

Sure it is no big problem handling and working with 500g free bromine but it would be much less of a hassle if it could be generated and used in situ.

Freaky

(Hive Addict)

05-23-03 04:27

No 434945

You might want to use GAA as solvent. You can also try SPB instead of oxone. At least, it has proven to work in my lab (but not in a designer drug synthesis

The faster you run, the quicker you die.

(Hive Addict)

05-27-03 02:03

No 435829

Doesen't anybody in the whole hive have a theory why it doesn't work? Not even a mod?

Edit

The reaction doesn't work with GAA/NaBr/H2SO4/DCM/H2O2 either, but as soon as bromine is generated separately from NaBr/H2SO4/DCM/H2O2 and the DCM/Br2 is added to GAA/propiophenone it runs smoothly. WHY?!

Freaky

(Hive Addict)

05-27-03 02:48

No 435834

I found the answer myself and it was actually quite simple

Freaky

(Hive Bee)

05-27-03 03:19

No 435836

Please share your findings Barium :) What went wrong?

Cops are not there to help you, they're there to bust you.

(Hive Addict)

05-27-03 04:56

No 435853

Water fuck things up here. It can be tolerated to a certain point, but above about 30-40% water in the reaction mixture the reaction dies. What really puzzles me is that the two-phase systems doesn't work.

Freaky

(Hive Addict)

05-27-03 11:23

No 435903

What's the pH of the mix with 30-40% water? just curious.

(Moderator)

05-27-03 18:16

No 435962

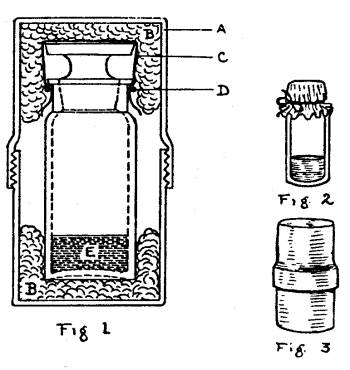

This improvised apparatus may bee helpful

The apparatus illustrated was used for brominating an organic compound, under pressure. At first an ordinary pressure-flask was used, equipped with a porcelain stopper and rubber gasket, as in a citrate of magnesia bottle. But it was suspected that the rubber gasket was being attacked by the bromine. to a pressure-bottle was desired in which nothing but glass would be exposed so the action of the hot bromine and reaction-mixture.

In the sectional view in Figure 1. A is a two-piece cylindrical aluminum box, shown in perspective in Figure 3, and originally intended as a shipping container for the wide-mouthed glass-stoppered bacteriological sample-bottle within. B and B are two wads of cotton. C is a Piece of muslin tied over the stopper and neck of the bottle with the string D (as shown in Figure 2). E is the reaction mixture. When the two halves of the box are screwed together, the wads of cotton are compressed and hold the stopper firmly in the bottle. A long string is then tied around the box, allowing it to be lowered into the steam-bath and to be removed when the desired length of time has elapsed.

The piece of cloth tied over the top of the bottle prevents the falling out of the stopper in case the box is inadvertently opened in an inverted position.

Chemistry is our Covalent Bond

(Hive Addict)

06-09-03 03:06

No 438810

(Rated as: excellent)

Example 1.

Arrange a gas generator and gas GAA with HBr to make a 40% solution. Dissolve 100 mmol propiophenone in some GAA and add 100 mmol HBr as the 40% HBr/GAA. With good stirring, add 100 mmol 30% H2O2 dropwise while keeping the temperature between 15 and 25°C. This gives a 90-97% yield of alpha-bromopropiophenone, which is as good yield as with a regular bromination.

But why not make use of the generated HBr formed in a regular bromination.

Example 2.

To 200 mmol propiophenone in 20 ml GAA add 100 mmol Br2 dissolved in 20 ml GAA dropwise (use a pressure equalized addition funnel) with cooling to keep the temperature between 15-25°C. When all bromine has been added start adding 100 mmol H2O2 as a 30% solution while keeping the temperature in the same range.

The latter method makes use of all formed HBr by converting it to Br2 again. Thus no bromine is wasted.

Freaky

(Hive Addict)

06-09-03 03:21

No 438813

I don't want to start a new thread for this so I carry on here instead.

When aminating e.g. alpha-bromopropiophenone with dimethylamine to N,N-dimethylcathinone all the methods I've found use slightly more than two moles amine/mol bromopropiophenone. One mol amine is used as acid scavenger and one mol amine replaces the bromine. But why don't use one mol NaHCO3 as acid scavenger instead? I have UTFSE and searched all the patents I could find but no luck. To use a bicarbonate seems so obvious, but have I missed something even more obvious here?

Edit

Ok, of course the bicarbonate is too weak to liberate the amine from the amine hydrobromide also formed. K2CO3 should do the job though, but is it likely to hurt the bromopropiophenone? I was thinking along the line of adding bromopropiophenone to the amine dissolved toluene in the precense of saturated aqueous K2CO3.

Freaky

(Hive Addict)

06-09-03 06:24

No 438840

you'll end up with some carbonate salts (just something to be aware of- not that it makes a huge difference)

(Hive Addict)

06-09-03 07:06

No 438845

No carbonates will survive since the reaction between the bromoketone and amine produces HBr, and the post-reaction workup includes acidification with hydrochloric acid to separate the product from any remaining bromoketone.

Freaky

(Hive Addict)

06-09-03 15:39

No 438919

I missed that very obvious item.

Act quickly or not at all.

(Hive Bee)

06-10-03 06:32

No 439058

(Rated as: good idea!)

Since I feel slightly guilty for not trying to help out on your original question (for what my opinion is worth...), I'll try this one.

Firstly, congratualtions on the second in-situ bromination method, what an excellent idea! Just make sure to use enough GAA to dissolve the liberated HBr (I notice sometimes that some sneaks out towards the end). Also, when doing the bromination on ring-methoxy propiophenones, I tend to keep the temperature at 0oC rather than 15-25oC; when brominating 4-methoxypropiophenone without cooling, the solution turned black and the yield was lower than usual. I think this is because the liberated bromide ion is poorly solvated in GAA, making it a better nucleophile and more likely to cause demethylation.

I don't think potassium carbonate will cause too much damage to the bromoketone. Since it isn't a nucleophilic base like hydroxide, there won't be a tendancy for nucleophilic substitution, meaning less decomposition. A bee friend of mine washes his bromoketones with potassium carbonate during workup, so it can't be too unhealthy, although I stick to sodium bicarbonate. NaOH does an excellent job of destroying bromoketones and I suppose gives the appropriate hydroxy-ketone in a rather exothermic reaction.

Also, a patent which may come in useful for those who don't like working with bromoketones and want to aminate the propiophenone as is; the catch is the reaction of an amine with bromine. Make sure to keep the temperature low! The method is patented by Kamlet, but no yields are given: Patent US2155194. This could be a nice route to consider if we could find another suitable source of N+ instead of using toxic haloamines.

(Hive Addict)

06-10-03 08:51

No 439077

(Rated as: excellent)

US Patent 2155194

Preparation of Alpha-Alkylaminoacylophenones

Abstract:

Alpha-alkylaminoacylophenones were prepared exclusively by halogenating and acylophenone and reacting the resultant halo-compound with an excess of alkylamine. Thus, in the preparation of alpha-methylaminopropiophenone, the common procedure involved the bromination of propiophenone and reacting the halo-compound with excess of methylamine. In this patent, alkyl-N-halogenated amines are generated in order to avoid formation and use of the alpha-halo compounds above, which are lachrymators and vesicants. It is also advantageous in that excess alkylamine is not required, thereby limiting over-alkylation of the nitrogen. It has been found that alpha-alkylaminoacylophenones may be obtained in one step by reacting an acylophenone with an alkyl-N-halogenated amines in a suitable solvent and in the presence of an alkaline substance.

CH3NH2 + NaOH + Br2 à NaBr + CH3NHBr

C6H5COCH2R + R’ NHXà C6H5CO-CH-R-NH-R’+ HX

By the term “alkaline substance”, it is to be understood that the substance shall have an aqueous pH of higher value than the alkylaminoacylophenone being prepared. Such compounds include the hydroxides and carbonates of ammonia and the alkali metals, the oxides and hydroxides of the alkali-earth metals, the quat salt hydroxides and the alkylamines, proper.

Example Procedure:

A halogen (e.g. bromine) is added in small portions to a well-cooled aqueous or alcoholic solution of one mole of alkylamine and one mole of alkali-metal hydroxide (or two moles of alkylamine) until one mole of the halogen has been dissolved. The temperature of the solution must not exceed 10*C during this addition. One mole of acylophenone dissolved in a miscible solvent such as alcohol, is now added and the mixture is agitated at a temperature lower than 15*C while adding slowly a solution of one-mole-equivalent of an alkaline substance. After stirring for two hour, the reaction mix is neutralized to litmus with HCl acid, diluted with water and unreacted acylophenone is extracted with ether. From the aqueous residue ( which comprises a solution of alpha-methylaminopropiophenone hydrochloride) the free base may be obtained in the usual manner by alkalinization and extraction with an organic solvent.

Alternatively, an aqueous solution of alkyl-N-halo-amine and an alkaline substance (alkylamine) may be agitated with an acylophenone dissolved in a water-immiscible solvent, such as benzene, at a temperature not exceeding 25*C for two hours. By dissolving the reagents in mutually immiscible solvents, the strongly exothermic reaction is somewhat moderated and a simple means is provided for separating the final end-products of the reaction.

Example 1:

Bromine is added in small portions to a well-cooled solution of 35g of methylamine and 40g of caustic soda in one liter of 95% alcohol at –5*C until a total of 160g of (50.3ml) has been added. The temperature of the solution should never exceed 10*C during the addition. 135g of propiophenone is now added and the mixture is agitated while a cold solution of 40g of caustic soda in 50ml of water is added in a thin stream. After stirring for two hours at a temperature below 15*C, the alcohol is distilled off under vacuum and the residue is dissolved in two liters of 1N HCl acid. Unchanged propiophenone is extracted with two successive 250ml portions of ether and the residual acid-aqueous solution of alpha-methylaminopropiophenone HCl is neutralized to litmus with a concentrated solution of sodium carbonate. It may now submitted to reduction by hydrogenation at 3-4 atm in the presence of Pd/C, Pt/C or Raney Nickel.

Example 2:

Bromine is added to a well-cooled solution of 95g of methylamine in one liter of water at –5*C in small portions until a total of 160g (50.3ml) has been added. The temperature of the solution should never be allowed to exceed 10*C during the addition. 135g of propiophenone dissolved in one liter of benzene is now added and the mix is vigorously agitated for two hours with efficient external cooling to keep the temperature below 25*C. The components of the reaction mix are now allowed to stratify and the aqueous solution of methylamine hydrobromide is separated from the benzene solution alpha-methylaminopropiophenone. The latter is neutralized to litmus with a conc. alcoholic solution of hydrochloric acid and the crystalline precipitate that forms is removed by filtration. By solution in alcohol and reprecipitation with acetone, white crystals of alpha-methylaminopropiophenone hydrochloride that had; MP: 179*C.

Table 1

R / R’ / MP of HCl Salt in *C

H/Me/219

Do/Et/228

Me/Me/179

Do/Et/182

Do/n-Pro/182

Do/iso-Pro/212

Do/n-Butyl/159

Do/n-Amyl/154

Et/Me/191

Do/Et/196

n-Pro/Me/181

The products of these reactions can be catalytically hydrogenated to their respective ephedrines in near quantitative yields with Pt/C or Pd/C or Raney Nickel

Act quickly or not at all.