(Hive Addict)

05-14-04 13:49

No 507191

(Rated as: excellent)

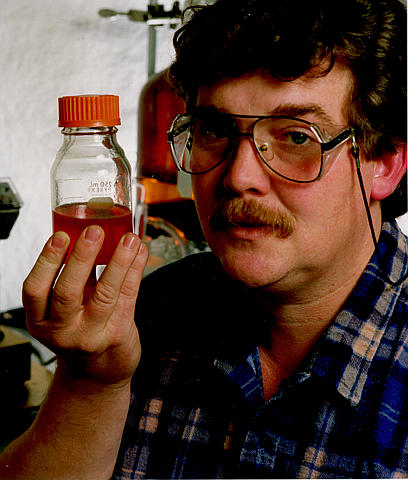

A bottle of freshly prepared levulinic acid from paper mill sludge

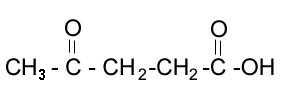

Preparation of levulinic acid from hexose sugars

Levulinic acid is a major product of the controlled degradation of hexose sugars by acids. Because the supply of hexoses from cellulose-containing plant material is immense and replenishable, conversion of such materials into a single chemical product meets one of the requirements for a basic chemical raw material.

The reactive nature shown by the keto and carboxyl groups meets the second requirement. Although levulinic acid has been known since the 1870's, when many of its reactions were first established, it has never reached commercial use in any significant volume.

Hexoses are convertible to levulinic acids by essentially a process of dehydration and cleavage of a mole of formic acid. The theoretical yield from a hexose is 64.5%, but the literature as reviewed by Wiggings (Advances in carbohydrate chem 4, 306-314 (1950)) shows that only about two thirds the theoretical yield can be attained; the balance proceeds to insoluble residues. Substantially the same yields from cellulose in Douglas fir sawdust were amply demonstrated by Frost and Kurth in 1951 (Tappi 34, 80-86 (1951); C.A. 45, 4441).

Formation of levulinic acid from low-cost cellulosic products overcomes one of the major difficulties encountered in other processes.

The preparation of levulinic acid from carbohydrates by the action of mineral acids is known from G. J. Mulder (J. Prakt. Chem. 21, 219 (1840) cited in Patent US5189215).

Early work on levulinic acid involved reacting different carbohydrate sources with mineral acids.

Levulinic acid has been produced by the action of acids on carbohydrates such as:

- glucose;

- galactose and sucrose

Wiggins, "Utilization of Sucrose" (Advance in Carbohydrate Chemistry, 4, 306-314 (1949))

Thomas, et al., "Studies on Levulinic Acid. I. Its Preparation from Carbohydrates by Digestion with Hydrochloric Acid Under Pressure" (J.S.C.I. Jun. 8, vol 53, 2324-2328 (1931));

- fructose, glucosamine, chitose, sorbose, deoxypentoses, and hexose

Patent US3258481

Patent US2206311;

- cane sugar and starch

Patent US2270328;

- disaccharide and polysaccharide unions

Wiggins, "Utilization of Sucrose" (Advance in Carbohydrate Chemistry, 4, 306-314 (1949)).

Here is the procedure from Organic Syntheses coll vol 1 p 335:

http://www.orgsyn.org/orgsyn/buttons.asp

1. Procedure

To a solution of 500 g. (1.46 moles) of cane sugar (Note 1) in 1 l. of water in a 2-l. flask is added 250 cc. of concentrated hydrochloric acid (sp. gr. 1.16). The flask is heated on a steam bath for twenty-four hours, during which time considerable carbonization takes place. The black solid is filtered off with suction and washed with 300 cc. of water. The filtrate is placed in a large evaporating dish on a steam bath and allowed to evaporate overnight. The black solid residue obtained on the following morning is ground to a powder and placed in a folded filter paper of 34-cm. diameter. This is placed in a 25-cm. funnel fitted with a water-cooled 12-l. flask as described on p. 375. The solid is extracted with 500 cc. of ether for six to eight hours. The ether is distilled and the residue (Note 2) fractionated under reduced pressure. The fraction distilling at 150–160°/15 mm. or 135–140°/10 mm. forms a rather dark liquid which does not completely solidify on cooling.

On redistillation under reduced pressure a fraction boiling over a range of not more than 2° (e.g., 137–139°/10 mm.) is obtained with very little loss; this fraction solidifies almost completely at 30°. The yield is 72–76 g. (21–22 per cent of the theoretical amount).

2. Notes

1. Equally good results may be obtained with starch; the mixture however, must be warmed more slowly as it is apt to foam at the outset.

2. When larger quantities of levulinic acid are to be prepared it has been found by the checkers to be more convenient to fractionally distil the first filtrate under reduced pressure, without evaporating to dryness and extracting with ether. In this case a considerable quantity of tarry residue remains in the distilling flask. The yields are equally good.

A good yielding procedure is found in Patent US5859263, which prepares levulinic acid from starch in a reactive extrusion process with yields of about 48% which is about 70% of theoretical.

Reduction of levulinic acid

Reduction of levulinic acid first yields 4-hydroxyvaleric acid, which, as the free acid, lactonizes readily to gamma-valerolactone (lactone of 4-hydroxyvaleric acid). The sodium salt of gamma-hydroxyvaleric acid can be obtained, as described by Rhodium in:

Sodium 4-Hydroxyvalerate, a Novel GHB Analog

../rhodium

/4-methy

Levulinic acid has been reduced to gamma-valerolactone by means of:

- sodium in alcohol

J. Am. Chem. Soc. 48, 3163-65 (1926);

- sodium amalgam

J. Gen. Chem. USSR 9, 924-931 (1939); C.A. 34, 368;

- sodium borohydride

J. Am. Chem. Soc. 71, 122-125 (1949);

- lithium borohydride

J. Am. Chem. Soc. 71, 3245-46 (1949);

- aluminium amalgam

Bul. Sci. Fakultat Terkult. Kyushu Imp. Univ. Fukuova 11, 86-90 (1944); C.A. 43, 5367

I hereby challenge everyone to beat this in OTC'ness.. ![]()

http://www.geocities.com/eric_vornoff/go

(Hive Addict)

05-14-04 15:03

No 507202

"1,4-butanediol dinitrates and butanetriols are obtained by Pb anode oxidation of levulinic acid"

Fichter, Fr. and Herndl, J.

Helv. Chim. Acta 25, 229-240 (1942);

C.A. 36, 5713

http://www.geocities.com/eric_vornoff/go

(Heavyweight Chempion(eer))

05-14-04 15:21

No 507204

That is really OTC!!

BTW, I told you several times not to post those old pics of me. Especially not the ones showing my red ears. How am I ever going to be able to seduce Aztec now??

Severe Aztecoholic and President of Sooty's fanclub - Sooty for President!!

(Hive Addict)

05-14-04 16:33

No 507213

Shave off the moustache, and give her say 3 grams of gamma-valerolactone

BTW ning, I saw you were looking for a malonic acid preparation recently. You might want to check this out:

"Malonic acid is obtained by treatment of levulinic acid with ozone."

Nakazaki, M. J. Japan Chem. Soc. 3, 108-110 (1949); C.A. 46, 6288

http://www.geocities.com/eric_vornoff/go

(Hive Bee)

09-11-04 03:14

No 530834

Can't get more uncontrolable than sugar, Prohibition Church's worst nightmare is reality, GREAT POST Dr. Vitus!

Only downside seems these reductions that are not OTC. Guess what, sodium dithionit redeuce levulinic acid in acceptable yields, see Post 497065 (Ganesha: "dithionite aldehyde/ketone reductions part II", Novel Discourse)

(Moderator)

09-14-04 18:19

No 531353

(Rated as: good read)

The following articles/abstracts have been located, scanned and uploaded

J. Am. Chem. Soc. 71, 122-125 (1949)

C.A. 43, 5367

J. Am. Chem. Soc. 71, 3245-46 (1949)

J. Am. Chem. Soc. 48, 3163-65 (1926)

Chemistry is our Covalent Bond

(Hive Addict)

09-14-04 23:16

No 531402

Meerwein-Ponndorf-Verley reduction (aluminium isopropoxide, which is OTC) should work with the free acid, unless it forms insoluble salts, then the next options would be using a salt or an ester of levulinic acid.

fear fear hate hate